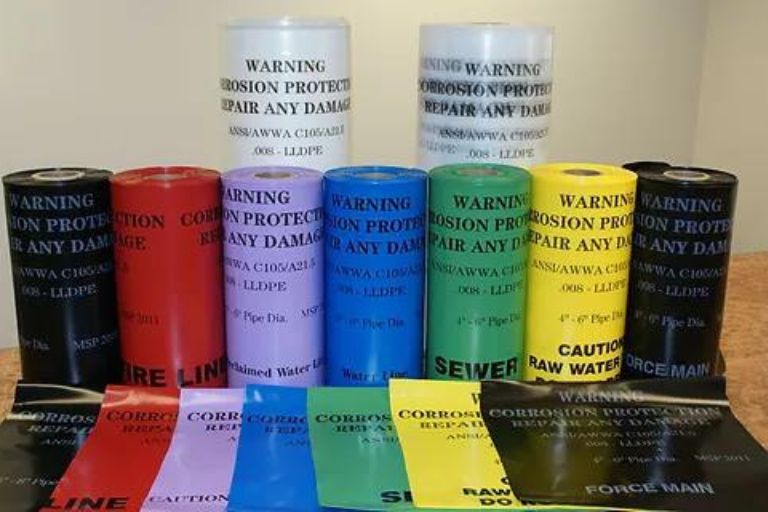

Often employed in the water and waste water sectors, polyethylene encasement is a protective covering meant to prevent corrosion of ductile iron pipes. Both towns and businesses alike choose this creative solution since it guarantees the dependability and lifetime of the pipeline infrastructure.

Advantages of polyethylene encasing

The capacity of polyethylene encasement to stop corrosion is among its main advantages. When ductile iron pipes come into contact with some soils and environmental factors, they will corrode. The polyethylene encasement serves as a barrier, preventing corrosive elements from invading the pipe and therefore increasing its lifetime.

Financial Effectiveness

One reasonably priced way to guard ductile iron pipelines is polyethylene encasement. Polyethylene encasement requires little maintenance, is somewhat cheap when compared to other corrosion protection techniques, and is quick to install. For major pipeline projects, this cost economy makes it appealing.

Simple Assembly

Polyethylene encasement may be installed fast and with simple technique. This simplicity of installation lowers labour expenses and lessens disturbance during the pipeline building operation. On-site wrapping of the pipes by contractors guarantees a close and safe fit.

Applications of Polyelene Encasement

Municipal water systems make great use of polyethylene encasement. For their water distribution systems, cities and towns depend on ductile iron pipes. Municipalities may guarantee the long-term performance of their water infrastructure by employing polyethylene encasement, therefore lowering the demand for expensive repairs and replacements.

Sewage Systems

The strong character of the effluents in waste water systems increases the corrosion risk. In these demanding conditions, polyethylene encasement offers a consistent way to guard ductile iron pipelines. It guarantees effective waste water management and helps the pipes to remain structurally sound.

Practical Uses in Industry

Using polyelene encasement for their ductile iron pipes helps industrial establishments as well. Many times, these pipes carry different chemicals and compounds capable of causing corrosion. Acting as a protective shield, polyethylene encasement helps to stop chemical reactions and maintain pipeline integrity.

Ductile Encasement Wrap Manufacturers’ Function

High-quality polyethylene encasement solutions are much dependent on the makers of Ductile Encasement Wrap Manufacturer. These companies follow rigorous quality control policies to create dependable, long-lasting encasement covers compliant with industry requirements. Their knowledge guarantees that the encasement guards ductile iron pipes against corrosion rather well.

Development and Innovation

To keep their products always better, top manufacturers commit in research and development. To improve polyethylene encasement’s performance, they investigate novel materials, technologies, and manufacturing techniques. More effective and efficient techniques for safeguarding ductile iron pipelines follow from this creativity.

Customary Solutions

Manufacturers of ductile encasement wraps provide bespoke solutions to satisfy particular requirements for various projects. By customizing the encasement coverings to fit different pipe diameters and forms, one guarantees an exact and safe fit. Custom solutions give different pipeline uses flexibility and adaptability.

Polyethylene Encasement Tubing Manufacturers’ Role

Polyethylene Encasement Tubing Manufacturer tubes that satisfy the strict industry standards. To guarantee the tubing is robust and efficient in shielding ductile iron pipes, they apply cutting-edge manufacturing technologies and premium materials.

Applicability Versatility

Applications for polyethylene encasement tube are many and they are flexible. From water and waste water systems to industrial pipelines, the tubing offers a dependable protective coating that increases the lifetime of ductile iron pipes. varying project requirements call for varying sized and length tubes produced by manufacturers.

Dedication to Environmental Protection

Prominent producers of polyethylene encasement tubing are dedicated to environmental sustainability. Their manufacturing techniques include environmentally friendly methods and make use of recyclable materials. This dedication to sustainability guarantees that the encasement solutions are not only sensible but also ecologically benign.

Conclusion

Among the several advantages polyethylene encasement for ductile iron pipes provides are corrosion resistance, economy, and simple installation. Municipal water systems, waste water treatment plants, and industry uses all around depend on it to guard pipeline infrastructure. Providing high-quality, creative, and unique solutions to satisfy the various needs of these sectors depends much on the producers of ductile encasement wrap and polyethylene encasement tubing. Selecting dependable producers, such Mountain States Plastics, helps you guarantee the ductile iron pipes’ long-term durability and performance. Visit mountainstatesplastics.com for additional details.