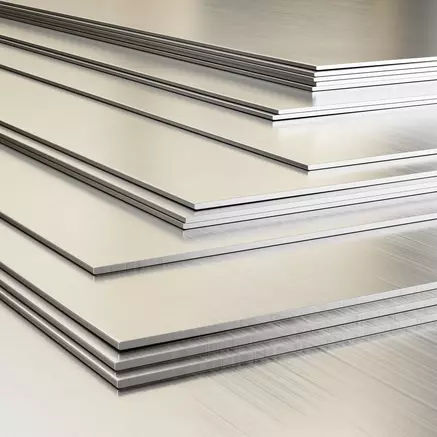

Aluminium sheets are an important aspect of contemporary construction because they are strong, flexible, and resistant to rust. There are many kinds of aluminium sheets, but two stand out for how useful and good-looking they are: Aluminium Perforated Sheet and Anodized Aluminium Sheets. Both have unique qualities that make them useful for a wide range of purposes, from building designs to industrial usage. This article will talk about the features, advantages, and uses of these two kinds of aluminium sheets.

What does an aluminium perforated sheet look like?

A form of metal sheet called an Aluminium Perforated Sheet contains holes, slots, or ornamental patterns punched into it. The procedure of perforation makes the aluminium sheet light and flexible while keeping its strength. Depending on how they will be used, these sheets may be made with holes of varied shapes, sizes, and configurations. Aluminium sheets with holes in them are typically employed in places where air, light, or sound needs to go through. This makes them great for ventilation panels, filters, and architectural designs that look good.

The main benefits of aluminium perforated sheets

One of the best things about Aluminium Perforated Sheets is how long they last. Aluminium is a popular option for outdoor use since it doesn’t corrode. Also, perforated sheets are typically used to reduce noise since the holes assist in absorbing and spreading sound. These sheets are also quite flexible since they may be cut, moulded, and put in a number of different ways. Perforated aluminium sheets are a great option for both utilitarian and ornamental uses, from cladding to facades.

What is a sheet of Anodized aluminium?

Aluminium that has gone through an electrolytic process called anodising is termed an Anodized aluminium sheet. This technique makes the natural oxide coating on the surface of the aluminium thicker, stronger, and less likely to rust. Anodising also lets you dye metal different colours, which makes it look good and protects it at the same time. People typically employ Anodized aluminium sheets to give kitchen equipment, outside cladding and signs a high-end look.

Benefits of Anodized Aluminium Sheets

Anodising has a number of unique benefits that make Anodized Aluminium Sheets a very popular material. The Anodized surface is significantly tougher and less likely to be scratched than untreated aluminium. This makes it last longer in tough conditions. The anodising procedure also provides the sheet with a smooth, glossy, or matte texture that makes it seem better. Anodized aluminium is great for decorative uses in architecture and interior design since it comes in a broad variety of colours. It also protects against the weather so that you may use it indoors and outside.

Why should you use Anodized and perforated aluminium sheets?

Choosing the correct material for your project is really important for making sure it works. Aluminium perforated sheets are strong and flexible and may be used to make one-of-a-kind patterns. They are great for both utilitarian and ornamental purposes. Anodized aluminium sheet, on the other hand, are more durable, resistant to corrosion, and come in a variety of beautiful finishes that are great for high-end uses. Both kinds of aluminium sheets are quite useful and beautiful, making them great for any project.

Conclusion

Aluminium perforated sheets and Anodized aluminium sheets are very flexible, long-lasting, and may be used in a lot of different ways. Because of their special features, they are great for many fields, such as architecture, building, and interior design. Aluminium sheets come in two sorts: useful and attractive. Both types may be used for different things, including ventilation or architectural covering. Go to Dinco.ae for professional assistance and high-quality resources if you want to learn more about these items.

FAQs:

1. What is the difference between Aluminium Perforated Sheets and Anodized Aluminium Sheets?

The main difference is in the manufacturing process. Perforated sheets are punched with holes, while anodized sheets are treated to enhance their surface durability and appearance.

2. Can Aluminium Perforated Sheets be used outdoors?

Yes, aluminium is naturally resistant to corrosion, making perforated sheets a great option for outdoor use in harsh weather conditions.

3. What colors are available for Anodized Aluminium Sheets?

Anodized aluminium sheets come in a wide range of colors, from natural metallic finishes to vibrant hues, depending on the anodizing process.

4. Are Aluminium Perforated Sheets customizable?

Yes, perforated sheets can be customized in terms of hole size, shape, and pattern, making them suitable for various design and functional needs.

5. Can Anodized Aluminium Sheets be used for interior design?

Yes, anodized aluminium is often used in interior design applications due to its elegant finish and durable surface.